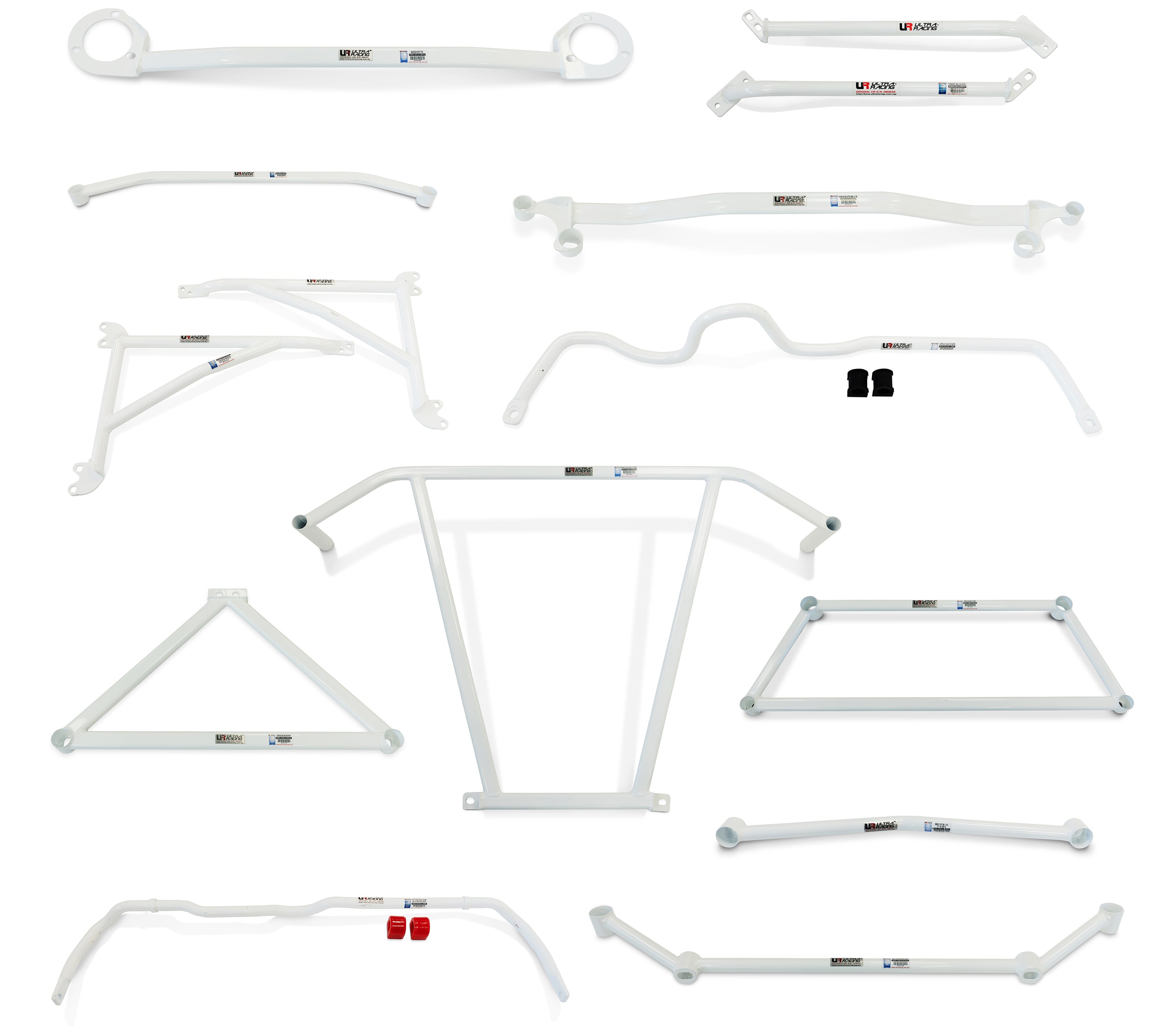

Ultra Racing meticulously choose each material to guarantee optimal performance and safety. Our brackets are crafted from steel plates measuring 4mm to 5mm in thickness, while the hollow steel tubes and oval tubes range from 1.2mm to 1.6mm in thickness. These materials are thoughtfully selected to ensure that our bars maintain rigidity and strength, preserving consistent geometry at all times, while also being designed to crumple during an impact for safety reasons. Rest assured, all our raw materials undergo rigorous testing, yielding satisfactory results.

PRODUCT DEVELOPMENT TESTING

For Ultra Racing to reach the desired certification, strict performance tests are conducted. The bars are bolted to three different types of jigs to simulate the load that occurs on road and beyond. Once all three tests have been completed the bars are then performance tested on track. Only once all these tests are completed and passed will the bars go into mass production.

-

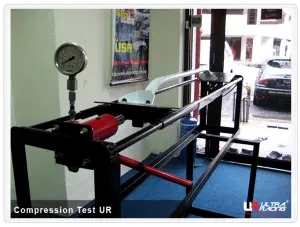

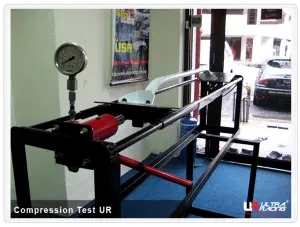

COMPRESSION TEST

The compression test is when forces are applied along both sides of the bar. This measures maximum compression force that the bar can withstand making sure it surpasses any force that fast road or track use will create.

-

TORSION TEST

The next test is the torsion test, for this test torque is applied to one side of the bar. This will record the amount of twist that has occurred under the applied pressure.

-

FLEX TEST

The third and final jig is to test the flex. Torque is applied to both ends to simulate the bar under heavy load which occurs in fast cornering or heavy braking.

STEEL vs ALUMINIUM

Firstly, it's important to note that steel surpasses aluminum in strength when comparing materials of identical size and thickness. To achieve the same level of strength as steel, aluminum alloys typically need to be twice as thick (e.g., steel 4mm = aluminum 8mm). However, as aluminum thickness increases to match steel strength, the weight savings become less pronounced. Additionally, while there are exotic materials and alloys capable of matching steel's strength, their production costs are astronomically high, making them cost-ineffective for mass production.